Advanced AI Manufacturing Solutions

We deliver innovative AI-driven tools to optimize production, improve efficiency, and ensure quality across all manufacturing processes.

Transforming Manufacturing with AI

Our AI solutions revolutionize manufacturing workflows by enhancing automation, reducing errors, and increasing productivity, ensuring businesses stay competitive and innovative in a fast-paced industry.

Predictive Maintenance Benefits

Utilize AI to predict equipment failures before they happen, minimizing downtime and reducing costly repairs, ensuring smooth and continuous manufacturing operations.

Quality Control Enhancement

Implement AI-powered inspection systems that detect defects and inconsistencies in real-time, improving product quality and reducing waste throughout the production line.

Supply Chain Optimization

AI algorithms analyze supply chain data to forecast demand, manage inventory, and optimize logistics, helping manufacturers reduce costs and improve delivery times.

Process Automation Efficiency

Automate repetitive tasks using AI-driven robotics and software, freeing up human resources for more complex and strategic manufacturing activities.

Energy Management Systems

Employ AI to monitor and optimize energy consumption across manufacturing plants, lowering costs and supporting sustainability goals with intelligent adjustments.

Custom Manufacturing Solutions

Leverage AI to tailor manufacturing processes to specific product requirements, enhancing flexibility and enabling mass customization with precision.

Workforce Safety Improvements

Use AI-powered monitoring and predictive analytics to identify and mitigate workplace hazards, ensuring a safer manufacturing environment for all employees.

Real-Time Data Analytics

Access continuous, AI-driven data insights to make informed decisions, quickly adapt to changes, and maintain high operational standards in manufacturing facilities.

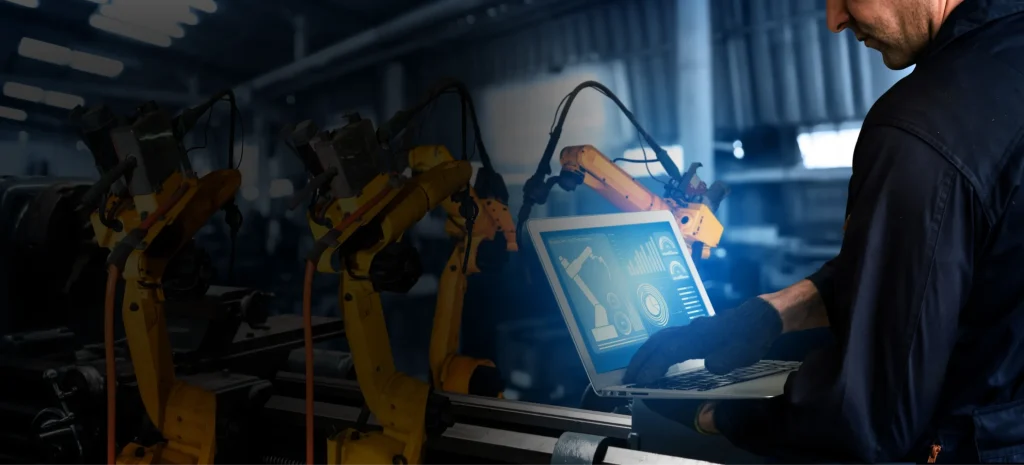

Advanced AI Technologies Driving Manufacturing Industry Success

Our cutting-edge AI tools help manufacturers improve efficiency, quality, and safety, while reducing costs and driving innovation across all production stages for long-term business growth.

Predictive Maintenance Systems

Prevent costly equipment breakdowns.

Automated Quality Control

Ensure flawless product standards.

Supply Chain Analytics

Optimize logistics and inventory.

Energy Consumption Monitoring

Reduce waste, save costs.

Safety Risk Detection

Protect workers proactively.

Custom Process Automation

Tailor workflows efficiently.

Key Benefits of AI Integration in Manufacturing

Implementing AI technologies in manufacturing enhances productivity, reduces operational costs, and drives innovation for sustainable competitive advantage.

Cost Reduction

AI solutions help lower production costs by optimizing processes and minimizing waste throughout manufacturing operations efficiently and effectively.

Quality Improvement

Automated inspection powered by AI ensures higher product quality, reducing defects and maintaining consistent manufacturing standards across batches.

Enhanced Safety

AI monitors real-time safety risks, enabling proactive measures that protect workers and prevent workplace accidents in manufacturing environments.

Increased Efficiency

AI streamlines workflows, accelerates production cycles, and improves resource management to boost overall operational efficiency.

Predictive Analytics

AI analyzes data to predict equipment failures, enabling timely maintenance and avoiding costly downtime in manufacturing facilities.

Supply Chain

AI optimizes supply chain management through better demand forecasting, inventory control, and logistics planning for smooth operations.

Advanced AI Technologies Transform Manufacturing Operations Today

Integrate cutting-edge AI tools to revolutionize your manufacturing processes for greater precision and productivity.

Empower Your Manufacturing With AI Solutions

Transform your manufacturing operations with AI-driven technologies designed to boost efficiency, reduce downtime, and improve product quality across all production stages.

Predictive Maintenance

Use AI-powered predictive maintenance to foresee equipment failures before they happen, reducing costly downtime and improving operational reliability in your manufacturing process.

Quality Control

Implement AI-driven quality control systems that automatically detect defects and ensure consistent product standards, minimizing waste and boosting customer satisfaction.

Supply Chain

Optimize your supply chain management with AI analytics for better demand forecasting, inventory control, and supplier coordination, increasing overall efficiency.

Process Automation

Automate repetitive tasks using AI solutions that increase productivity, free up human resources, and ensure precision in manufacturing workflows.

Safety Monitoring

Enhance workplace safety through AI-powered monitoring systems that identify hazards in real-time, helping to prevent accidents and maintain compliance.

Energy Management

Leverage AI tools to monitor and optimize energy consumption throughout your manufacturing facilities, reducing costs and supporting sustainability goals.

Innovative AI Solutions for Manufacturing

Orca delivers cutting-edge AI tools that streamline manufacturing operations, improve accuracy, and boost overall productivity for businesses of all sizes.

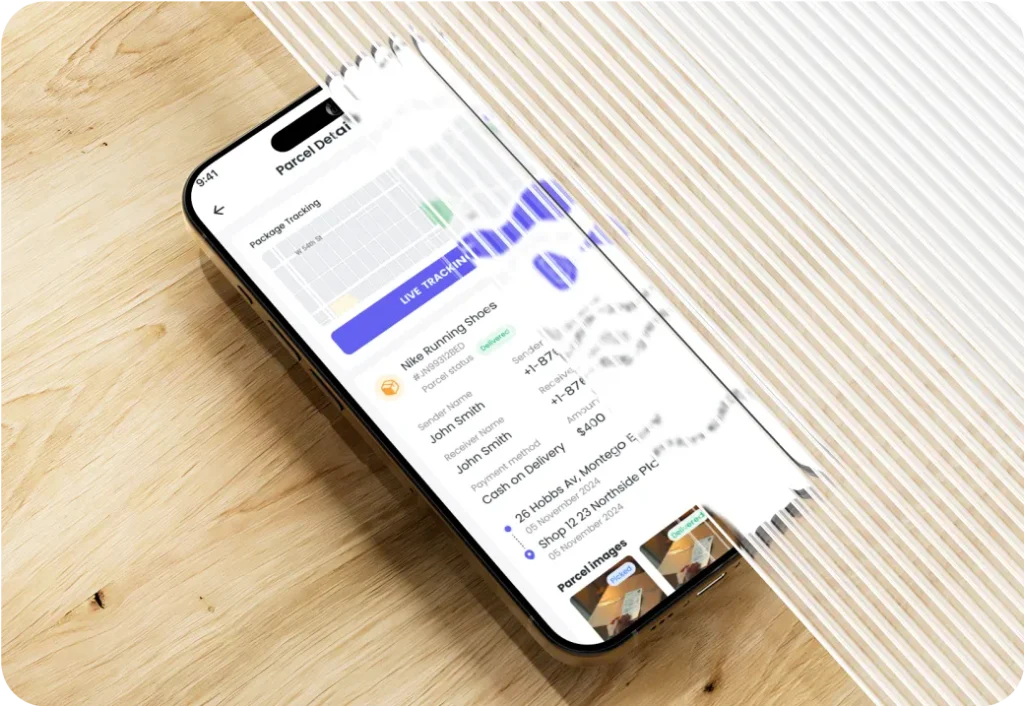

Tech Transit – Smart Delivery, Simplified

Revolutionizing last-mile delivery with real-time tracking, intuitive UX, and seamless order management.

54%

ROI Growth

78%

Improvement Delivery

Fuse AI With You Manufacturing

Boost efficiency, reduce waste, and improve product quality consistently.

Streamline Manufacturing Processes

Our AI solutions optimize workflows, enhance productivity, and reduce operational costs across every stage of manufacturing operations.

DL Frameworks

Microsoft .Net

Python

Nodejs

Java

GO

Modules/Toolkits

Python

Nodejs

Visualization tools

Microsoft .Net

Nodejs

GO

Programming Language

Nodejs

Java

Microsoft .Net

Cloud providers

Python

GO

Nodejs

Java

Python Frameworks

GO

Nodejs

Java

Python

FAQs

We provide AI tools for process automation, predictive maintenance, quality control, supply chain optimization, and real-time data analysis.

AI automates routine tasks, predicts equipment failures, and optimizes production schedules to boost overall efficiency and reduce downtime.

Yes, by minimizing waste, improving resource management, and preventing costly machine breakdowns, AI significantly lowers operational expenses.

Absolutely. Our AI solutions are tailored to fit specific industry needs, whether automotive, electronics, textiles, or others.

Integration time varies but typically takes a few weeks, depending on system complexity and project scope.

Yes, we offer continuous monitoring, updates, and maintenance to ensure your AI systems perform optimally.

Definitely. AI-driven quality control detects defects early and maintains high product standards throughout production.

AI needs historical production data, sensor inputs, and real-time operational data to deliver accurate insights and predictions.

Need a Consultation?

Drop us a line! We are here to answer your questions 24/7.

Call

09421 9232 2321